Grain storage has evolved significantly from traditional methods like godowns and warehouses to modern steel silos. This transformation was driven by the need to optimize space, reduce labor, minimize losses, and enhance food security. However, storing grain in silos presents its own challenges—primarily due to temperature and humidity variations. This article compares traditional and modern storage methods, examines preservation techniques, and highlights why grain chilling is emerging as the most effective solution for long-term grain storage.

Traditional Storage vs. Silo Storage

Conventional Godowns and Warehouses

Historically, grains were stored in bags stacked in warehouses or godowns, which required:

- Large land areas due to stacking height limitations

- Significant manual labor

- Regular maintenance to prevent rodent and pest infestation

As land costs rose and labor availability declined, these methods became less sustainable. Moreover, while natural air movement in warehouses helped with aeration, grains were still vulnerable to temperature swings, infestation, and mold development.

Scientific Storage in Silos

Silos offered a more mechanized, space-efficient, and manageable alternative. Benefits include:

- Better accounting of incoming/outgoing grain

- Reduced land footprint

- Minimal manual handling

- Lower grain losses due to controlled environments

However, storing grain in steel silos introduced new challenges, particularly related to temperature and moisture buildup due to the respiration of grains in a closed environment.

Challenges of Silo Storage

Though silos reduce handling and space issues, they lack natural aeration, unlike godowns. The following problems may arise:

- Exothermic respiration raises internal silo temperatures

- Increased moisture content triggers mold growth and mycotoxins

- Insect infestation and starch degradation

- Inaccurate temperature readings from poorly placed sensors

- Over-drying or loss of grain mass and moisture

These issues demand advanced grain preservation methods to maintain grain quality over extended storage periods.

Grain Preservation Techniques in Silos

- Aeration and Temperature Monitoring

- Aeration systems help remove hot spots and manage grain temperature.

- Temperature monitoring cables trigger alerts when grain temperature exceeds 5°C above ambient.

- However, in temperate and tropical climates, aeration often fails due to high humidity and high temperature, making it unsuitable for cooling.

Presently, the industry is still facing an issue of inefficient aeration methods and its effects on grain, by recirculating grain. But when the storage is in dozens of silos, the conveying equipment becomes too complex for recirculation of grain.

Presently, the industry is still facing an issue of inefficient aeration methods and its effects on grain, by recirculating grain. But when the storage is in dozens of silos, the conveying equipment becomes too complex for recirculation of grain.

- Essential for killing live infestations using:

- Recirculating Phosphine (PH₃) gas or aluminiumtablets using probes

- Carbon dioxide (CO₂) treatments

- Requires airtight sealing of silos to suffocate pests

- Fumigation is a reactive solution and does not prevent re-infestation if temperature and moisture are not controlled.

- Nitrogen Treatment

- Creates a low-oxygen, high-nitrogen environment to eliminate pests and microbial activity.

- Helps prevent oxidation and spoilage.

- However, it is costly and does not address long-term grain respiration once O₂ levels rise again.

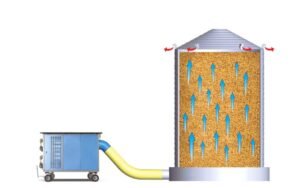

Grain Chilling: The Future of Scientific Grain Storage

Grain chilling involves reducing the temperature of stored grain to below 20°C, rendering insects and their eggs inactive and halting the respiration process. It is a proactive preservation method that maintains grain quality and quantity over time. It eliminates the risk of infestation, development of molds and mycotoxins, starch loss and mass loss, discoloration of grain and moisture loss of grains as well.

Benefits of Grain Chilling

- Prevents infestation, mold, and mycotoxin development

- Reduces respiration, thus minimizing mass, starch, and moisture loss

- Maintains grain freshness and color

- Reduces the need for fumigation

- Provides a complementary drying effect for high-moisture grain

- Maintains moisture content / no over drying.

- Works independently of external weather conditions

Ideal Preservation Strategy

If incoming grain is already infested:

- Initial fumigation is necessary to eliminate pests.

- Follow-up with grain chilling to maintain quality and prevent future infestations.

Conclusion

Grain chilling is rapidly emerging as the most effective, sustainable, and foolproof method for long-term grain preservation in silos. While conventional methods like fumigation and aeration still play supporting roles, they often fall short in high-temperature and high-humidity environments.

For countries with hot, tropical climates and ambitious food security goals, investing in grain chilling technology offers a path toward minimizing post-harvest losses, maintaining nutritional value, and ensuring food availability year-round.

The next series of article on Grain Chilling will cover the ROI of grain chillers, present scenario, future scope and more.

By Rajiv Iyer, Director & Vice President Global Sales, Grain Technik