Introduction

India’s maize sector has undergone steady expansion over the last decade, driven by rising demand from the poultry feed, starch, and ethanol industries. In 2023–24, the country produced approximately 35.7 million tonnes of maize grain (Agricultural & Processed Food Products Export Development Authority [APEDA], 2024). The FAO forecasts India’s aggregate maize production in 2024 at a record 38.1 million tonnes, driven by large sowings and strong domestic feed demand and According to the Third Advance Estimates released by India’s Ministry of Agriculture & Farmers’ Welfare, maize production in the 2024–25 agricultural year is estimated at 422.81 lakh metric tonnes (LMT), which equates to 42.281 million tonnes.

Alongside this grain output comes an equally significant volume of maize straw—also known as maize stover—which includes leaves, stalks, and cobs left after harvesting. Approx 3.0-4.0 ton of straw is produced per acre.

A conservative residue-to-product ratio (RPR) for maize is close to 1:1 (U.S. Department of Energy [DOE], 2019), meaning that for every tonne of maize grain, roughly one tonne of stover is generated. This places India’s potential annual maize straw output in the range of 30–35 million tonnes. While much of biomass is left to decompose or is burned in fields, organized collection and processing can transform this by-product into a high-value commodity across multiple sectors.

A conservative residue-to-product ratio (RPR) for maize is close to 1:1 (U.S. Department of Energy [DOE], 2019), meaning that for every tonne of maize grain, roughly one tonne of stover is generated. This places India’s potential annual maize straw output in the range of 30–35 million tonnes. While much of biomass is left to decompose or is burned in fields, organized collection and processing can transform this by-product into a high-value commodity across multiple sectors.

For Farmer Producer Organisations (FPOs), Milk Producer Companies (MPCs), cooperatives, and agri-startups, maize straw presents a scalable business opportunity that aligns with both income diversification and sustainability goals, while also generating substantial rural employment and strengthening dry fodder security for dairy animals.

For Farmer Producer Organisations (FPOs), Milk Producer Companies (MPCs), cooperatives, and agri-startups, maize straw presents a scalable business opportunity that aligns with both income diversification and sustainability goals, while also generating substantial rural employment and strengthening dry fodder security for dairy animals.

- Livestock Feed: Bales, Silage, and Densified Products

Market Rationale

Maize straw is a critical roughage source in mixed crop–livestock systems. The International Maize and Wheat Improvement Centre (CIMMYT) has documented cases where maize stover bales sold to smallholder dairy farmers at around INR 3.8 per kilogram, undercutting the cost of sorghum stover while maintaining acceptable nutritional value (CIMMYT, 2013). Moreover, breeding programs for dual-purpose maize have increased stover digestibility, making it a viable fodder base (Rai et al., 2021).

Processing Options

- Baled Stover: Direct field baling reduces labour dependence for farmers and ensures consistent feed supply for dairies.

- Multi-Enzyme Treatment: Enhances crude protein content and palatability, enabling higher feed conversion efficiency.

- Pelletized Feed Blocks: Compaction increases bulk density from ~94 kg/m³ to ~390 kg/m³, cutting transport costs by up to 60% over typical rural haul distances (University of the Philippines Los Baños [UPLB] & International Rice Research Institute [IRRI], 2023).

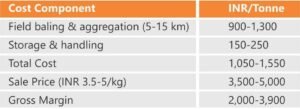

Economics of Straw Handling

Collection and transport costs for cereal straw, including maize, typically range between INR 900–1,300 per tonne for short hauls (5–15 km) (Council on Energy, Environment and Water [CEEW], 2023). With market prices in the range of INR 3,500–5,000 per tonne, gross margins can be INR 2,000–3,900 per tonne, before financing and storage costs. In Punjab, during each maize harvest, the delivered price of baled straw ranges from INR 1500 to INR 1800 per tonne.

- Renewable Energy: Bio-CNG, Biomass Pellets and Bioethanol

Bio-CNG through SATAT

The Sustainable Alternative Towards Affordable Transportation (SATAT) initiative by India’s Ministry of Petroleum & Natural Gas provides assured offtake for Compressed Bio-Gas (CBG) from agricultural residues (Ministry of Petroleum & Natural Gas [MoPNG], 2024). Additionally, lignocellulosic structure of maize straw makes it a suitable feedstock for anaerobic digestion, particularly when co-digested with animal manure.

Biomass Co-firing

The Ministry of Power encourages biomass co-firing in thermal power plants at a blending rate of 5–10%. Pellets and briquettes produced from maize straw can meet this demand, with procurement facilitated under the SAMARTH mission (Ministry of New & Renewable Energy [MNRE], 2025).

Second-Generation Ethanol

Research shows that maize stover can yield high levels of fermentable sugars after pretreatment, making it a suitable feedstock for second-generation ethanol plants (Menardo et al., 2013). With India’s ethanol blending program expanding, this could emerge as a niche yet profitable application.

- Specialty Material Applications

Agro-fiber Boards

Maize straw can be converted into particle boards or fiber panels for the furniture and packaging industries. MSME-scale production lines are already available, requiring modest capital investment.

Animal Bedding

The poultry and equine sectors pay for chopped stover due to its high absorbency and cushioning qualities.

Mushroom Cultivation

Properly pasteurized maize straw serves as an excellent substrate for mushroom production, opening a high-margin agribusiness avenue.

- Operational Blueprint for Rural Enterprises

Step 1: Residue Mapping

Identify maize-growing clusters and estimate accessible straw volumes using conservative removal rates of 33–50% to maintain soil cover (United Nations Economic and Social Commission for Asia and the Pacific [UN-ESCAP], 2023).

Step 2: Infrastructure & Logistics

Rent or purchase balers, rakes, and loaders. Build low-cost sheds for off-season storage to prevent moisture damage.

Step 3: Market Linkages

Sign seasonal supply agreements with local dairy cooperatives, bioenergy developers, and material processors. Include clauses for fuel price and moisture adjustments.

Step 4: Value Addition

Invest in small-scale multi-enzyme treatment units or pelletizers to increase the per-unit value of stover sold.

- Financial Snapshot

Value-added forms such as treated stover or pellets can raise prices by INR 1–1.8 per kilogram, boosting overall returns.

Conclusion

Maize straw represents a multi-stream business opportunity that fits perfectly into the operational capabilities of FPOs, MPCs, cooperatives, and agri-startups. By focusing on aggregation, densification, and targeted offtake agreements across feed, energy, and material sectors, rural enterprises can transform an underutilized residue into a dependable, scalable income source.

References are available on request.

by Dr. Simranjeet Kaur, Dr. Harsimran Kaur, Ph.D., School of Business Studies, Punjab Agricultural University

Dr. Harinder Singh

Excellent Enterprises, Khanna