Poultry production is a highly advanced sector within agriculture and plays a significant role in global food production. Feed accounts for about 70% of the total cost of poultry production, with approximately 95% of the feed cost allocated to meeting energy and protein requirements, and the remaining 5% for minerals, vitamins, and other feed additives. The poultry industry aims to meet the increasing demand for protein, but a key challenge is the availability and price volatility of feed ingredients. Balancing feed costs with feed quality is a major challenge for the industry.

Poultry production is a highly advanced sector within agriculture and plays a significant role in global food production. Feed accounts for about 70% of the total cost of poultry production, with approximately 95% of the feed cost allocated to meeting energy and protein requirements, and the remaining 5% for minerals, vitamins, and other feed additives. The poultry industry aims to meet the increasing demand for protein, but a key challenge is the availability and price volatility of feed ingredients. Balancing feed costs with feed quality is a major challenge for the industry.

Strategies to reduce poultry feed cost

1. Feed cost optimization is commonly achieved through least-cost formulation using software and precision nutrition, including synthetic amino acids like Lysine, Methionine, Threonine, Valine, Tryptophan, and Arginine. This practice has been common in the industry for the last three decades.

2. Enhancing dietary energy utilization is crucial and under constant investigation. Feed additives like exogenous enzymes and fat emulsifiers are used to improve digestion and nutrient absorption. Enzyme mixtures are commonly used in poultry feed.

2. Enhancing dietary energy utilization is crucial and under constant investigation. Feed additives like exogenous enzymes and fat emulsifiers are used to improve digestion and nutrient absorption. Enzyme mixtures are commonly used in poultry feed.

3. Cellular Energy: The latest strategy involves ensuring cellular metabolic efficiency by using Guanidinoacetic acid (GAA). GAA is a creatine precursor and a natural amino acid derivative. It is an important component of cellular metabolism and ensures optimal availability of ATP, which is the ultimate source of energy for the cell.

The animal’s digestive system converts the complex compounds found in the food (such as carbohydrates, proteins, and fats) into simpler compounds (like glucose, amino acids, and fatty acids) that can be absorbed through the intestinal wall. Once absorbed, these nutrients are further broken down through controlled oxidation in the body to produce chemical energy in the form of ATP in the mitochondria via the citric acid cycle.

The animal’s digestive system converts the complex compounds found in the food (such as carbohydrates, proteins, and fats) into simpler compounds (like glucose, amino acids, and fatty acids) that can be absorbed through the intestinal wall. Once absorbed, these nutrients are further broken down through controlled oxidation in the body to produce chemical energy in the form of ATP in the mitochondria via the citric acid cycle.

NSP-ase and emulsifiers are active in the gut, helping with the digestion of soluble NSPs and fats and improving the availability of nutrients for absorption, while GAA acts at a cellular level.

Adenosine triphosphate (ATP) and Cellular Energy

Adenosine triphosphate (ATP) is often known as the “energy currency” of the cell, as it provides readily available energy when the bond between the second and third phosphate groups is broken. When adenosine triphosphate (ATP) loses a phosphate group, it forms adenosine diphosphate (ADP) and releases around 8 kcal/mole of energy. ATP is rapidly utilized, with most molecules reacting within 40 minutes of formation. On any given day, a 2.5 kg bird can utilize the equivalent of up to 1 kg of ATP.

Birds need more ATP otherwise ATP deficiency can occur in following conditions:

- Rapid &fast growth

- Excitement or stress

- Low oxygen supply

Disturbed energy metabolism

Low feed consumption especially in extreme summer

The regeneration of ATP through the creatine and phosphocreatine system is crucial for fast-growing broiler chickens due to their increased need for muscle growth. GAA has been explored as a potential feed additive to improve energy utilization by boosting ATP regeneration through the creatine and phosphocreatine systems.

Guanidinoacetic acid (GAA) & Creatine

The synthesis of guanidinoacetic acid mainly occurs in the kidney. GAA is produced from the conditionally essential amino acids glycine and arginine through a reaction catalyzed by the enzyme L-arginine:glycineamidinotransferase (AGAT). Subsequently, GAA is methylated in the liver by S-adenosylmethionine (SAM) and is converted into creatine with the help of the catalyzing enzyme guanidinoacetate N-methyltransferase (GAMT). Two additional enzymes, methionine adenosyltransferase (MAT) and S-adenosylhomocysteine hydrolase, are also involved in the metabolism of GAA.

Birds can produce GAA and creatine, but the natural production is not enough to support the high performance of modern broilers. Therefore, supplementing GAA in their diet is advantageous. GAA relies on the body’s nutrients for methylation and enzyme synthesis to convert into creatine. However, this process can be compromised under stress, leading to poor creatine delivery and reduced performance. On the other hand, activated GAA, when added to the feed along with methyl donor and transferase enzymes, bypasses these processes and efficiently converts into creatine in the body. This ensures high creatine levels, energy conservation, and improved performance.

Birds can produce GAA and creatine, but the natural production is not enough to support the high performance of modern broilers. Therefore, supplementing GAA in their diet is advantageous. GAA relies on the body’s nutrients for methylation and enzyme synthesis to convert into creatine. However, this process can be compromised under stress, leading to poor creatine delivery and reduced performance. On the other hand, activated GAA, when added to the feed along with methyl donor and transferase enzymes, bypasses these processes and efficiently converts into creatine in the body. This ensures high creatine levels, energy conservation, and improved performance.

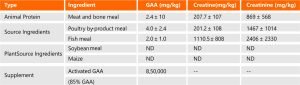

GAA (mg/kg) & Creatine (mg/kg) in different Feed Ingredients

Creatine is only found in animal protein sources. It is not reliably available from external sources because it is sensitive to heat, and the rendering process temperature can affect its levels in feed. Vegetable-based diets and their ingredients do not contain GAA & Creatine.

Supplementation of GAA in Poultry Feed

Supplementation of GAA in Poultry Feed

Dietary GAA has been proven to act as a precursor of creatine. Creatine is converted into phosphocreatine, which is a reserve source of phosphorus & energy, that will release its energy when there is an immediate need for basic source of energy like ATP.

GAA has been officially registered as an animal feed additive by the EFSA (European Food Safety Authority) (2009; 2022) & the FDA (U. S. Food and Drug Administration).

GAA supplements account for 40% less cost compared to creatine.

GAA exerts many non-creatine roles, including stimulation of insulin secretion, neuromodulation, and vasodilation.

GAA has an arginine-sparing potential of up to 149% in broilers, thus arginine is more readily available for metabolic processes other than GAA production.

Effects of GAA on FCR & growth performance

A meta-analysis of various experiments conducted by Khajali et al., 2020 concluded that Feed Conversion Ratio (FCR) improved by 4.5 to 8.8 points when broiler diets were supplemented with Guanidinoacetic acid (GAA) at doses between 0.6 and 1.2 g/kg. This supplementation had a positive impact on body weight. The consistent effects of adding GAA to the diet were attributed to improved energy utilization. Furthermore, adding GAA to the feed was found to restore broiler performance by compensating for reduced dietary energy content. GAA supplementation significantly enhanced the efficiency of energy utilization, resulting in significantly improved FCR.

Broiler diets supplemented with GAA at 0.6 to 1.2 g/kg also showed significant improvements in performance and a higher percentage of breast meat. Additionally, adding GAA to plant-based diets improved performance and carcass characteristics, including breast meat yield.

A recommended dose of 600 g/ton of feed of Activated Guanidinoacetic acid was found to lower the metabolizable energy level by 30-60 kcal/kg of feed.

Effects of GAA on meat quality

Pre-slaughter transportation accelerates energy consumption in broiler muscle, leading to stress-induced glycolysis and lactic acid accumulation. Including 1.2g/kg of GAA in broiler diets improves meat quality by reducing energy expenditure and delaying anaerobic glycolysis in the muscles. This supplementation may be effective in reducing myopathy severity. Additionally, including 0.12% GAA in broiler diets reduces breast myopathies such as woody breast and white striping.

Effect of GAA on heat stress

During heat stress, cellular energy demand increases and mitochondrial ATP generation decreases. Muscle energy reserves are utilized more, and enhancing the cellular creatine-phosphocreatine energy shuttle system may benefit broilers. GAA feeding improved survival during heat stress and reduced panting frequency.

Effects of GAA on fertility and semen quality

Semen quality is affected by Sertoli cell dysfunction and defective spermatogenesis. GAA, a precursor of creatine, is essential for Sertoli cell function and sperm energy metabolism. Feeding broiler breeders with GAA at 0.6 and 1.2 g/kg improved sperm penetration and fertility. Additionally, supplementing female breeder feed with GAA enhances the availability of creatine in eggs and offspring muscles, resulting in better postnatal performance.

Conclusions:

Guanidinoacetic acid (GAA) is an effective feed additive in poultry, reducing costs and improving performance. At 600 g/ton of feed, it enhances energy utilization, lowers costs, and improves feed conversion ratio, bird performance, meat yield, and overall meat quality. It also benefits reproduction performance in breeders and reduces heat stress mortality.

by Dr. Rais Rajpura, Anand Agricultural University, Anand